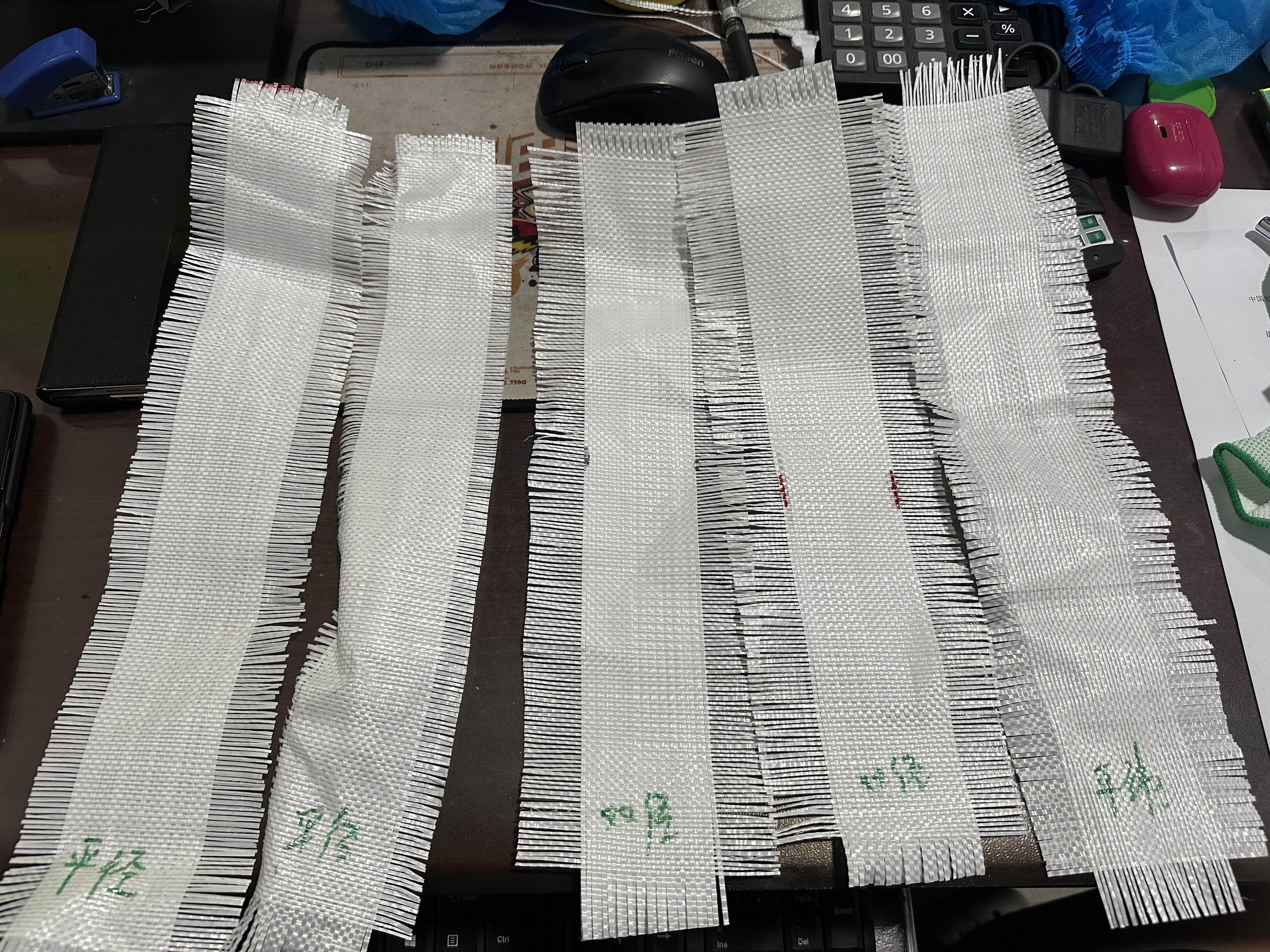

Tangshan Zongye Packaging successfully shipped two containers of bulk bags to Spain

Recently, Tangshan Zongye Packaging Co., LTD's production base presented a busy yet orderly scene. FIBC The successful loading of a batch of high-quality flexible intermediate bulk containers (FIBCs) into containers marks the completion of shipment for two full containers destined for a Spanish client, officially commencing their journey!